Manufacturers embrace AI & automation but face key barriers in 2025

Research from SYSPRO, conducted in collaboration with Frost & Sullivan, has found that complex manufacturers are showing strong interest in adopting smart technologies but face ongoing challenges during deployment.

Based on a survey of 128 manufacturers at the 2024 SPARK Customer Roadshow, data from an October 2024 Trends Webinar, and over 360 interviews with manufacturing leaders – a fifth of whom are based in Asia Pacific – the findings reveal a trend towards increased adoption of automation, artificial intelligence (AI), and industrial internet of things (IIOT) technologies in the manufacturing sector.

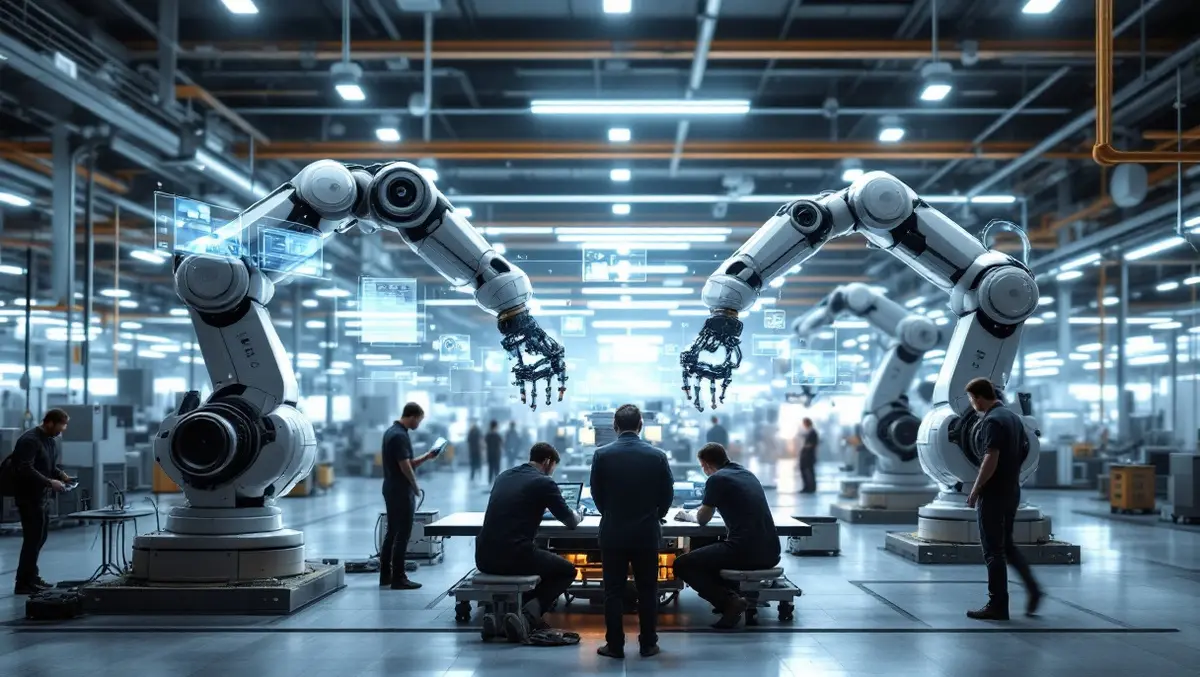

The data shows that 37% of manufacturers have begun using automation and robotics, while 19% are adopting AI and machine learning, and 18% are working with IIOT technologies.

The greatest priorities for digital transformation in 2025 are the implementation of AI and automation (40%), improving digital integration and access to real-time insights (29%), and managing costs associated with new technology adoption (24%).

Adoption rates vary across global markets. Nearly half (45%) of surveyed Chinese manufacturers are already employing emerging smart manufacturing technologies, suggesting that China leads the field compared to the United States, where manufacturers are still advancing towards widespread implementation.

Among all respondents, 40% prioritised AI and automation above other digital transformation initiatives. In total, 80% of those surveyed are currently directing resources to AI implementation or plan to do so in the near future. Of these, 12% have already deployed AI or are actively in the process of implementing it, 57% are researching potential use cases, and a further 11% intend to implement AI within the coming year.

Despite this eagerness for digital transformation, manufacturers report several technical barriers.

Almost one-third (30%) cited integration difficulties with new technology. Outdated systems are a challenge for 15% of respondents, leading to operational inefficiencies, while another 15% face limitations due to scalability issues as they try to future-proof their operations.

The provision of real-time data and analytics is another significant challenge in the sector. Four in ten leaders find they lack timely data to enable fast, informed decisions. Although analytics are seen as a potential solution, only 23% of manufacturers have made investment in analytics a key technology priority for the next year, and nearly a quarter (24%) indicated they are not using analytics at all.

Manufacturers also highlighted skilled labour shortages as a key challenge, with 30% ranking it as their top concern for 2025. Challenges with supply chain disruptions (23%) and cybersecurity issues (12%) were also selected as notable risks for the coming year.

Matthew Day, Chief Information Officer at Langs Building Supplies in Brisbane, Australia, commented on the integration of advanced technologies at his company. "I oversee all the business-critical IT systems in our production environment. We have recently completed a successful upgrade of our enterprise IT infrastructure, which provides us with remote access in a hybrid cloud setting."

"The subsequent improvements to digital integration across our environment enable us to utilise SYSPRO ERP for real-time insights and cost management while incorporating advanced technologies such as AI and automation into our production facility."

James Robinson, Head of Services for Asia Pacific at SYSPRO, spoke about the wider implications for the industry.

"Manufacturers clearly see smart technology as the key to overcoming workforce shortages and supply chain disruptions. However, adoption is still challenging. SYSPRO's ERP solutions are designed to simplify this transition, providing the flexibility and integration needed for real-world manufacturing environments."